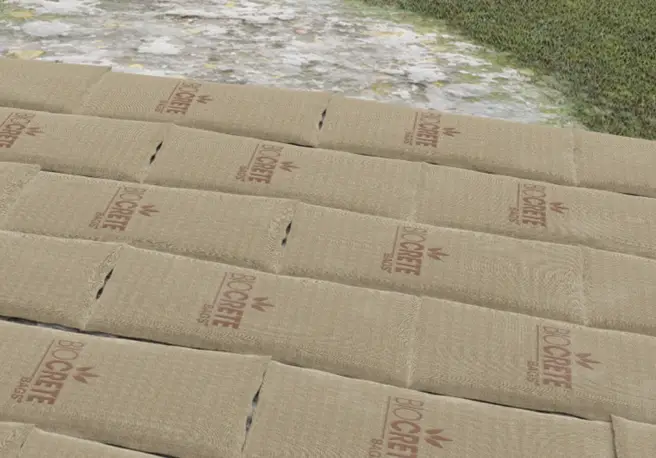

Biocrete Bags

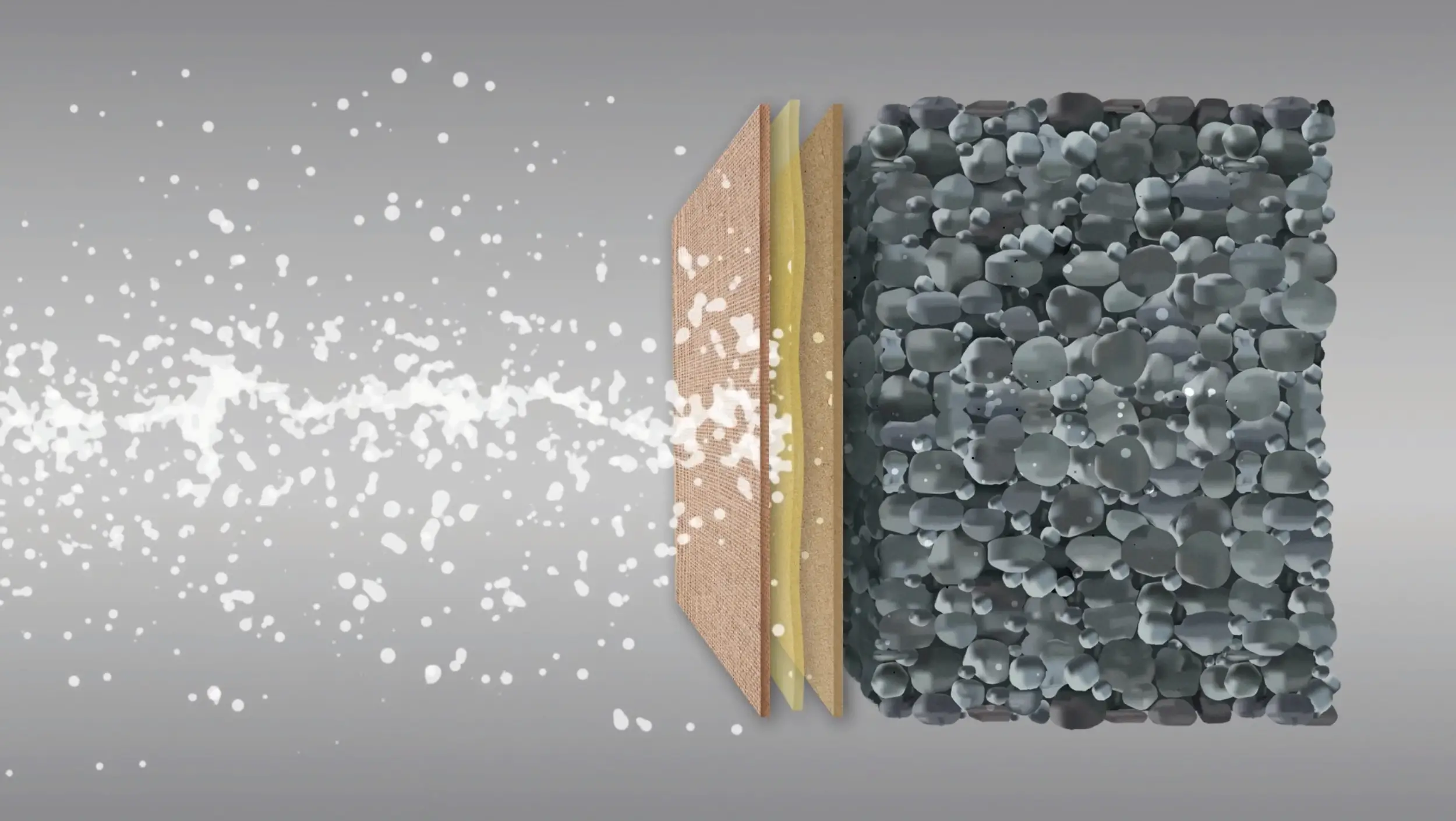

Biocrete Bags are uniquely designed Biodegradable Cement Bagwork solutions, used by engineers for building temporary concrete structures in wet and watercourse conditions.

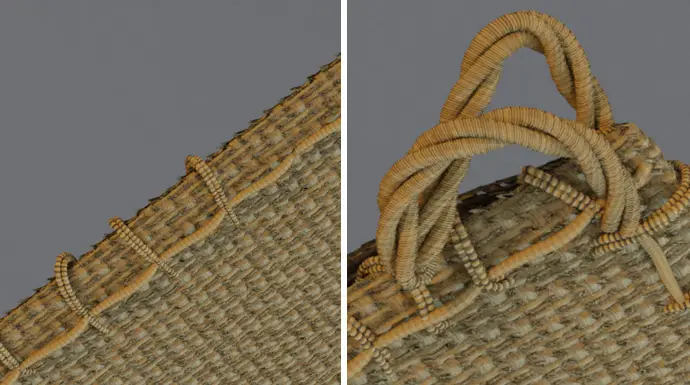

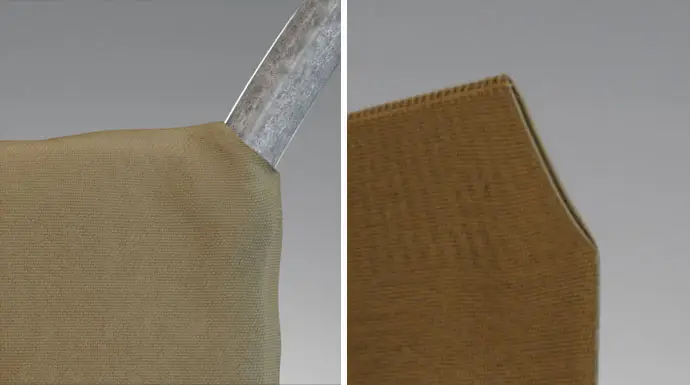

Made from an outer layer of burlap fibre, and an inner layer of recycled kraft paper, these bags are laminated using a proprietary biodegradable adhesive. Stitched using heavy-duty jute twine, manually double knotted at the end, strengthens the bag further to withstand extreme water pressure.

HIGH LIGHTS

Bag Placement

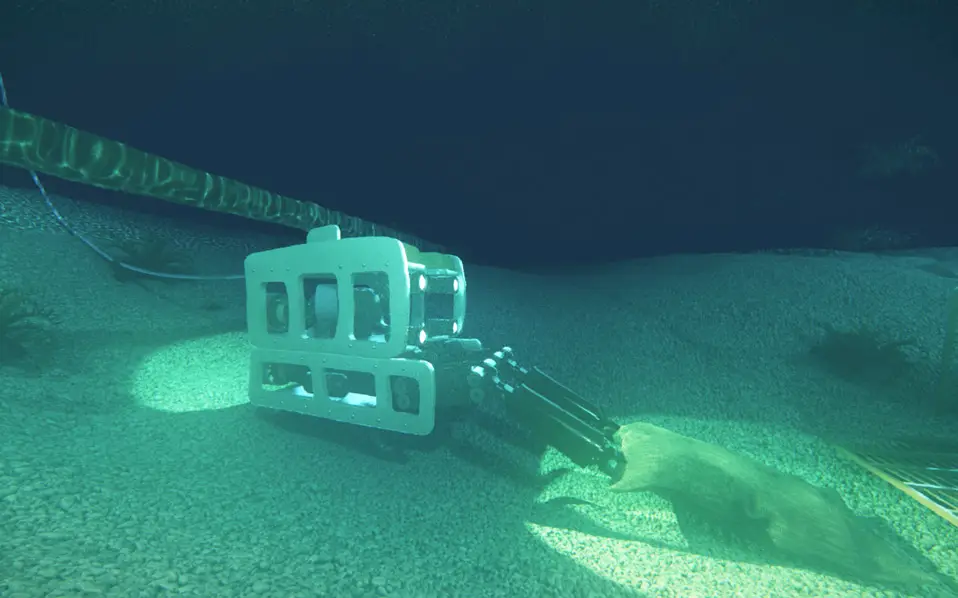

Biocrete Bags can be placed in Underwater,

Active Watercourse or Dry Areas for various uses.

Technical Specifications

single-size mentioned below:

| Outer Layer Material | Burlap / Jute |

| Inner Layer Material | Recycle Kraft Paper |

| Lamination Material | Biodegradable Adhesive |

| Dimension (L x B) | 535 mm x 410 mm |

| Weight (Empty) | 0.3 Kgs / 0.6 Lbs |

| Weight (Full) | 25.5 Kgs / 55.9 Lbs |

| Total Capacity | 25 Kgs / 55 Lbs |

| Bag Stitching | Heavy-duty Jute Twine |

HOW TO USE

Easy to use, Biocrete Bags require minimal manpower to fill them at the site. These bags have consistent shape and size and come with a maximum capacity of 25 kgs, ensuring ease of manual handling and eliminating any risk and hazards of handling.

SUSTAINABILITY

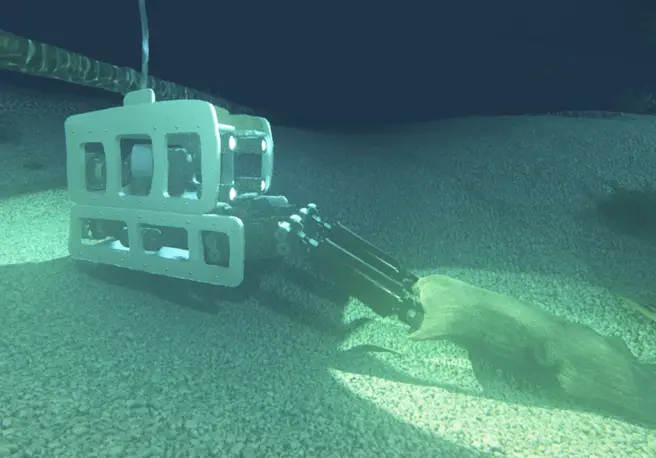

Most grout bags used for subsea and water stream applications are made of Polypropylene (PP) or Plastic, making it extremely dangerous and harmful for the water ecosystem.

Biocrete Bags offers a unique combination of 100% biodegradable material, making it Safe and Sustainable for underwater use.

Most grout bags used for subsea and water stream applications are made of Polypropylene (PP) or Plastic, making it extremely dangerous and harmful for the water ecosystem.

Biocrete Bags offers a unique combination of 100% biodegradable material, making it Safe and Sustainable for underwater use.

(Bags damage over time)

(Sand Inside)

(Concrete inside)

Sustainability

(Made of PP/Plastic)

(bigger & heavier)

Application

Biocrete Bags are a miracle! Use them for quick concretization or disaster management applications like:

Specially designed to provide strong protection against scouring and seabed degradation and also provide underwater pipeline support for oil, gas and other offshore projects.

Solutions for natural erosion threats, void filling, solving drainage problems to ensure ground stability.

Under extreme water conditions, these areas are susceptible to damages throughout the year.

Solutions for concrete road construction in interiors villages and low land areas, where landslides & flood makes roads extremely inaccessible.

Case Study

Case Study

ABOUT JP LAMINATORS

For over 3-decades, JP Laminators & Corrugators is one of the leading manufacturers and exporters of Laminated Jute and Paper Packaging products from India. We have developed and supplied Biocrete Bags to several global subsea projects for over a decade.

Our technologically-advanced manufacturing facility with a floor space over 20,000 sq. ft. is located near Kolkata, India.

Contact Us

For more information about Biocrete Bags or to place an enquiry,

Feel free to get in touch with us and we will get back to you soon.

SEND A MESSAGE

OUR OFFICE

JP Laminators & Corrugators

- PS QUBE, Unit No 1101, 11th Floor, Newtown, Kolkata, India - 700156.

- Srijit Aon

- +91 9831221535

- info@biocretebags.com